1. Exposing the Lucrative Truth of Lighting Upgrades Through Data

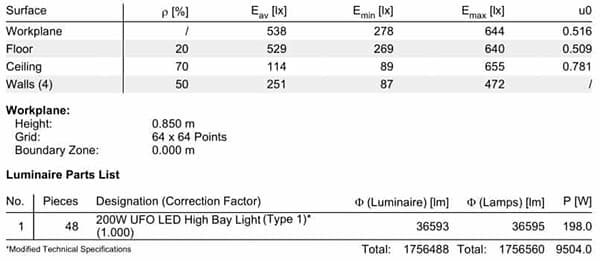

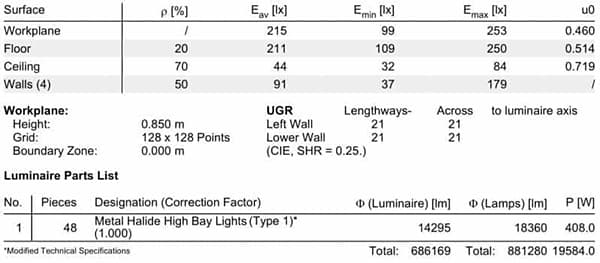

Are You Still Struggling with Sky-High Electricity Bills and Dim Workshop Lighting? Data reveals a shocking truth: 48 units of 400W metal halide lamps consume 85985 kWh annually, costing over $10000 in electricity, while 200W LED equivalents require only 41713 kWh – slashing energy consumption by 51.5%! Even more astonishingly, LED efficiency reaches 184.8 lumens per watt (File 01), 5.3 times higher than metal halide lamps (35.0 lm/W) – delivering 150% more illumination coverage with half the energy consumption!

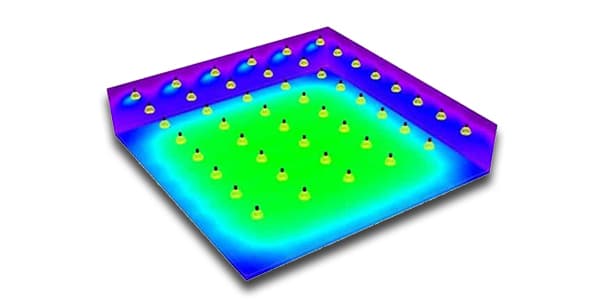

Light quality demonstrates a crushing advantage: LEDs deliver an average workplane illuminance of 538 lux (File 01), far surpassing the 215 lux of metal halide lamps (File 02), with minimum illuminance rising to 278 lux – eradicating dark zones in corners. Environmentally, LEDs cut annual carbon emissions by 22 tons (equivalent to planting 1100 trees), while metal halide lamps, plagued by rapid lumen decay and mercury contamination, have become an “ecological liability”.

If these numbers still don’t convince you – consider this: The electricity savings alone could fund a Tesla Model 3 in just three years!

2. Why Are Companies Rushing to Upgrade?

If ‘halving energy consumption’ has already caught your attention, the long lifespan and zero maintenance advantages of LEDs will completely revolutionize your choice – metal halide lamps last only 2.5 years on average (10000 hours), while LEDs boast a lifespan of 12 years (50000 hours)! For 48 lamps, metal halides require replacement twice a year at $50 per lamp, costing $4800 annually in maintenance, whereas LEDs are virtually maintenance-free for a decade – saving not just money, but also labor and downtime losses.

Even more critical is the long-term brightness consistency: Metal halide lamps suffer a 30% drop in light output after just one year, reducing illuminance from 215 lx to 150 lx, while LEDs maintain over 90% of their lumen output after five years. For high-intensity environments like factories and warehouses, LEDs support smart dimming and motion sensors, seamlessly adapting to production rhythms, whereas metal halide lamps require 5-10 minutes to restart, severely hampering efficiency.

Additionally, the flicker-free and UV-free characteristics of LEDs reduce worker eye strain and enhance operational safety – this isn’t just about cost savings; it’s an upgrade in productivity and responsibility.

3. From a 'Cost Black Hole' to the Ultimate 'Value Engine'

If you think LEDs are just about ‘saving electricity’, you’re missing their true profit-driving logic – Customized scenario adaptation turns every lamp into an efficiency booster: factories reduce sorting errors by 15% thanks to uniform lighting, sports venues ensure broadcast-ready lighting with instant on/off, and warehouses achieve zero blind spots through modular design.

Safety and compliance are even more critical: Metal halide lamps contain mercury, with disposal costs exceeding $200 per lamp, and they violate EU RoHS directives. In contrast, LEDs are UV-free and noise-free, eliminating material degradation and worker hearing damage at the source. Even more importantly, the 22-ton annual carbon reduction can be directly converted into carbon trading revenue or ESG financing leverage, boosting a company’s green premium by 10%-15%.

Over the next decade, the smart capabilities of LEDs will be the ultimate game-changer: Built-in IoT interfaces enable real-time energy monitoring, and time-based dimming slashes another 15% off electricity bills. Meanwhile, metal halide lamps face an impending countdown to obsolescence, with global phase-out trends leading to spare parts shortages.

Flexible collaboration and comprehensive support: We provide professional design assistance, paired with long-term warranty services, ensuring your lighting upgrade is seamless and accelerates your energy efficiency goals.

4. Two Steps to a 'Risk-Free' Energy Efficiency Revolution

Simply provide your space dimensions, and within 24 hours, you’ll receive a complete, scientifically-backed lighting solution

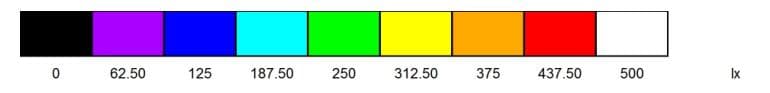

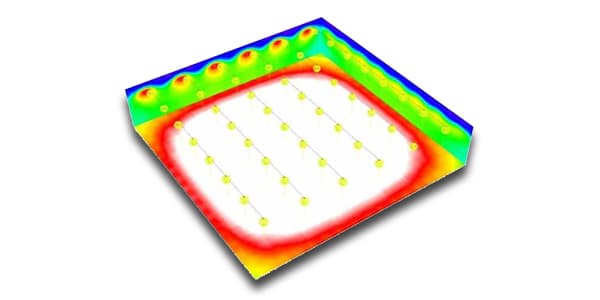

(1). Precision-matched solutions: Using DIALux’s 64×64-point grid accuracy (File 01), we generate 3D illuminance heatmaps, directly comparing the performance of LEDs versus metal halide lamps:

- The average workplane illuminance jumps from 215 lx to 538 lx (File 01 vs. File 02), eliminating dark zones entirely.

- Energy consumption simulations are precise down to each lamp: 48 LED units save $5312 annually in electricity costs (File 01), while the high mercury disposal costs of metal halide lamps ($200 per unit) are completely eliminated.

(2). Instant Action Entry Point:

Upload your space dimensions → Receive a customized report with 3D renderings.

Take Action Now: Scan the code to submit your dimensions, and by this time tomorrow, your energy efficiency upgrade plan will already be on its way.